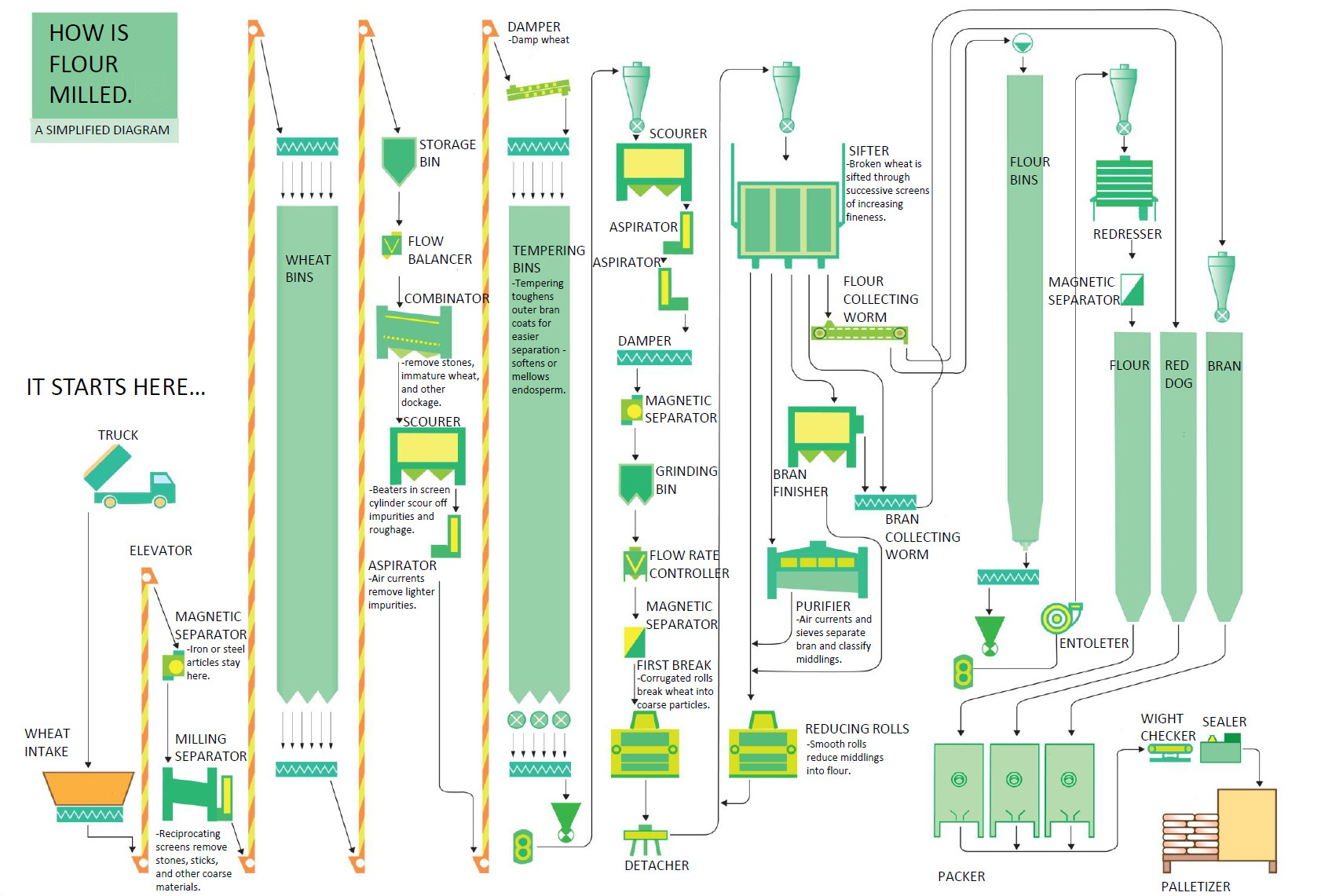

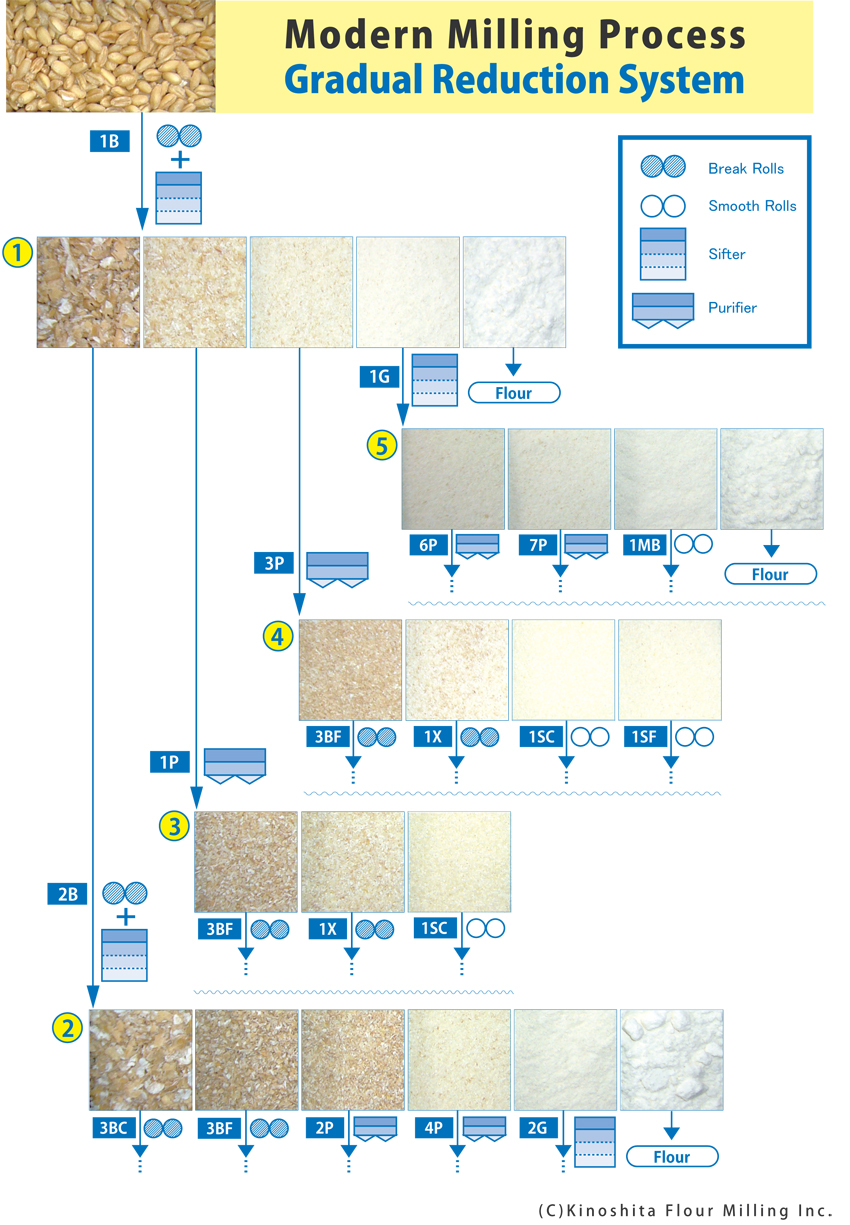

"Flour milling is considered an art", this is the opening sentence of WHEAT FLOUR MILLING by E. S. Posner & A. N. Hibbs. Today, every flour mill uses what is known as the gradual reduction system, a very mysterious and complicated way of milling. After undergoing several grinding cycles, the flour is classified into roughly 50 different categories, and then further grouped into 3 or 4 different types of flour according to their grades. As a result, the quality or character of wheat flour varies from flour mill to flour mill, even though they process the same wheat.

The reason why we practice this gradual reduction system is just to avoid the contamination of wheat bran into flour as much as we could, since speck, a small piece of bran, would damage the taste and the food texture of the Udon. For a better understanding of the milling flow and gradual reduction system, please see the pictures below.